- kansesan@kfore.co.in

- +91 9096627510

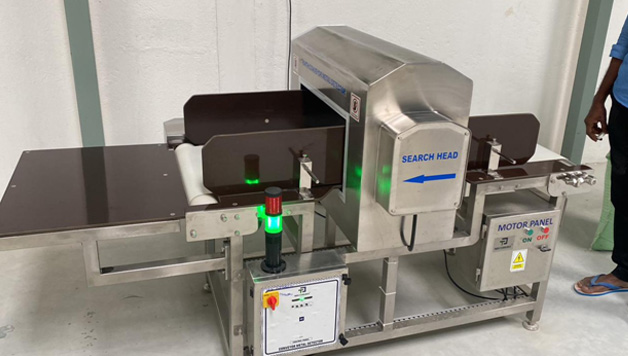

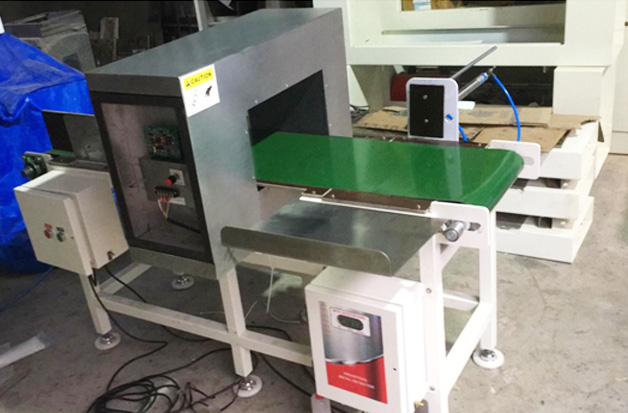

Post Packaging Systems

Food safety is a major concern for consumers and producers. While we like to think our food is clean, trace metals and particulates can contaminate our food. These unwanted particles mix with our food in processing facilities that employ heavy machinery and handling equipment to sort, package, and move consumables.

With the wear and tear of constant use, these machines can shed metal contaminants into the food products they handle. In 2015 alone, Unibright Foods recalled almost 50,000 pounds of meat in response to discovering "extraneous metal materials" from in-house machinery. Although unfortunate, such incidents remain a helpful reminder of how crucial it can be to use food metal detectors on production lines.

Being able to detect trace metals helps manufacturers prevent contaminated food from reaching consumers and ensures the safety of their products. Understanding what metals to look for and how to detect them are the two first steps to improving food quality at your facility. Advances in metal detection technology mean these devices can now sense even the slightest quantities of metal. The metal detectors themselves work by picking up on the magnetic permeability or conductivity of metal particulates. There are three main groups of metal types that they detect :

- Ferrous Metals (Mild Steel/Cast Iron) : Ferrous metals contain iron, an element with strong magnetic properties. Their magnetic properties make these metals especially easy to identify with metal detectors, which pick up on the magnetic field emitted by trace amounts of iron.

- Non-Ferrous Metals (Copper/Lead/Aluminum) : These metals lack iron and are not magnetic. However, they are still conductive. The electromagnetic resonances in these metals make them fairly easy to detect.

- Stainless Steel : Although stainless steel does contain iron, it does not possess strong magnetic properties. It is also less conductive than the other elements on this list, making it more challenging to detect. Environmental conditions such as moisture and high salinity can also interfere with detection.

X-ray inspection is necessary for non-metallic contaminants such as bone splinters, ceramic shards, stone fragments, and glass, as these particles are neither conductive nor magnetic. In conjunction with food metal detectors, X-ray systems can help detect the full spectrum of particulates found in food.